The cost of sealants is only a small proportion of the total cost of insulating glass, but they are very important for the durability and safety of the glass.

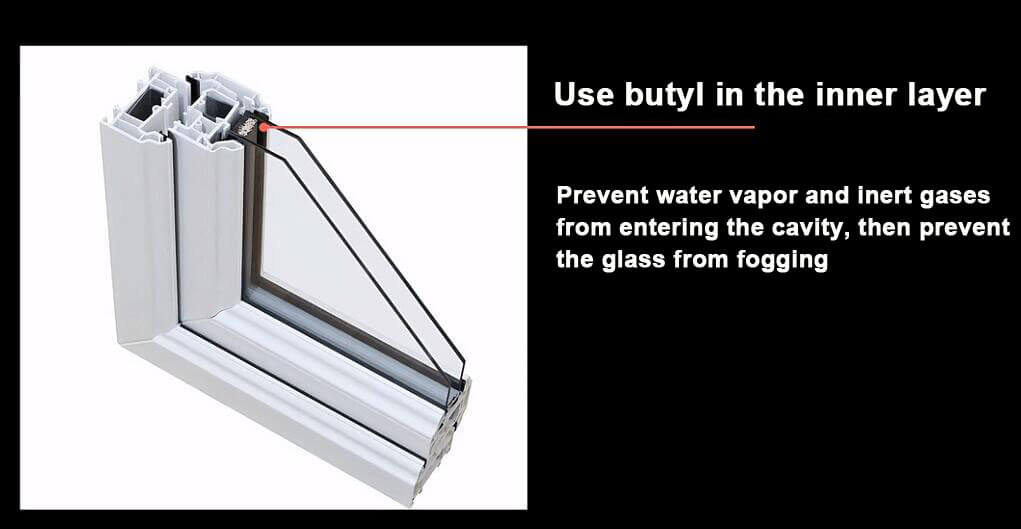

Insulating glass consists of two or more pieces of glass bonded with a spacer. Two kinds of sealants are required when assembling.

The first is butyl sealant, used in the inner layer. Its main function is to prevent water vapor and inert gases from entering the cavity. But butyl sealant has low adhesive strength and elasticity, so a secondary sealant is needed to ensure the structure stable.

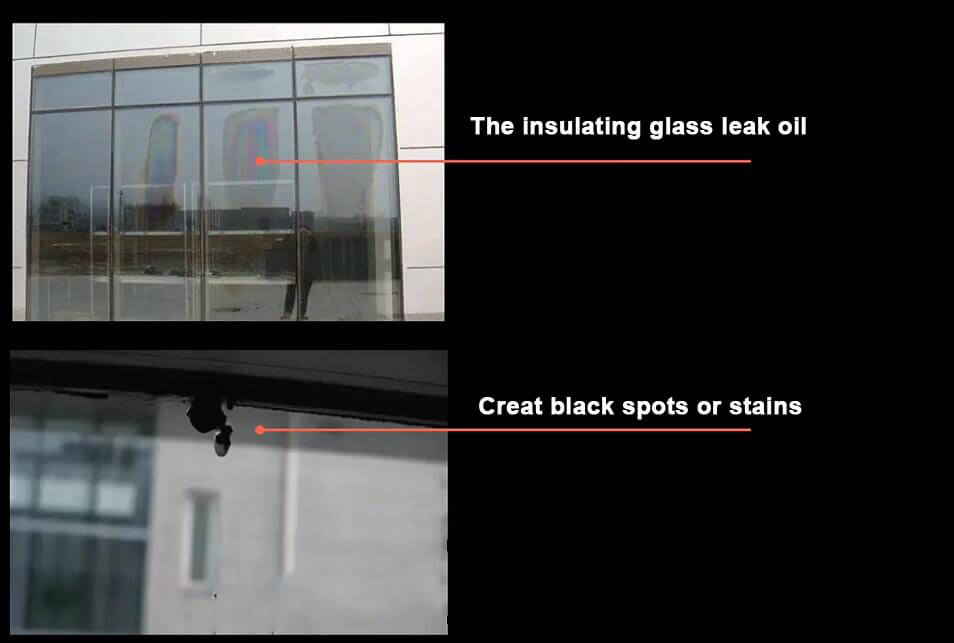

The widely used secondary sealant for insulating glass is silicone sealant. Some manufacturers replace a small amount of silicone oil with white oil to reduce costs. However, white oil can corrode the butyl sealant in the inner layer, leading to oil leaks and creating black spots or stains. These issues will result in seal failure.

After several years of use, insulating glass may develop fogging and water accumulation, losing its heat insulation, noise insulation, and waterproofing capabilities prematurely.

Therefore, it is essential to choose a silicone sealant without white oil as the secondary sealant for insulating glass. WS201 is specially designed for insulating glass, free from white oil, and offers excellent adhesive and elastic properties.